Sieving and filtration solutions to guarantee your product quality

We help manufacturers improve quality, efficiency and profitability. We will work with you to customize our standard products and find the best solution possible.

We will improve the quality of your final products

Assure your quality

Remove all oversize contamination, safeguarding your product quality and reputation.

Optimize your productivity

Our solutions deliver optimum screening efficiency, maximizing production capacities.

Maximize your profitability

Reduce your production downtime, product wastage and maintenance costs.

Industries we serve

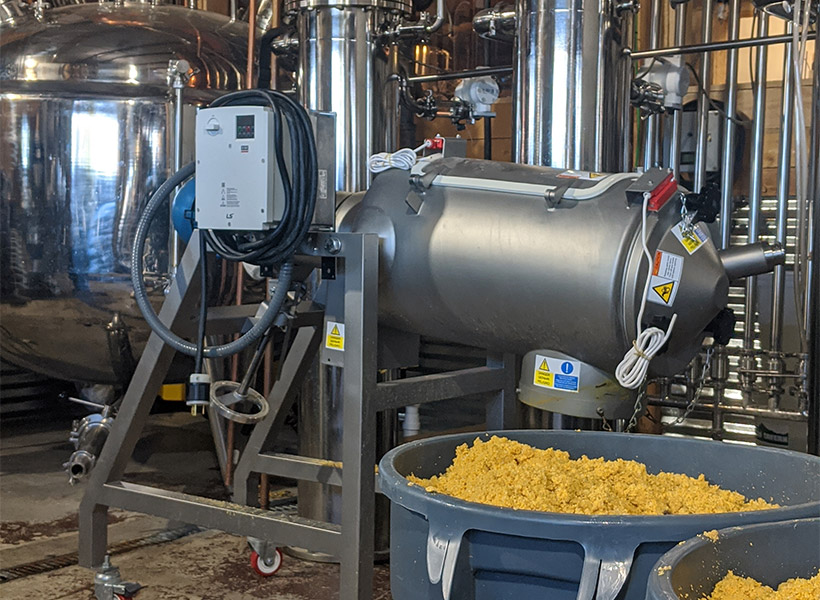

Russell Finex helps Nestlé safeguard product quality at its new 26,000 tonnes/year milk powder processing plant in Chile. Traditional rotary sifters were replaced with Russell Compact Sieve® units, to allow milk powder to be screened at a finer mesh size without reducing flow rates. GKN Aerospace ensures AM powders are qualified properly before and after use with the installation of two Russell AMPro® Sieve Stations. Efficiency is doubled with reduced handling and guaranteed turnaround times, whilst potential for cross contamination is eliminated. Extract Technology Ltd., a leading containment and aseptic systems manufacturer, integrates Russell Compact Sieve® units and Vibrasonic® Deblinding Systems. Located within their downflow booth to allow a pharmaceutical manufacturer to optimize powder production. Mondelēz International installs a Self-Cleaning Russell Eco Filter® to filter caramel for reuse. This results in a 20% reduction in product wastage and improves the wate disposal process. Jotun replaces rotary sieves with the Russell Compact Sieve® to eliminate any risk of product contamination when screening powder coatings. This sieve has a crevice free design, making it easy to dismantle and clean for quick colour changes.Russell Finex helps Nestlé safeguard product quality

AM powder recovery for the aerospace industry

Downflow booth screening solution

Filtering caramel at Mondelēz International

Screening fine powder coatings

A leader in the industry

Established in 1934, Russell Finex has become a worldwide leader in fine mesh separation technology, enjoying over 85 years of successful growth. We supply to over 140 countries with companies in the UK, USA, Belgium, India, China and Brazil.

Discover the sieving and filtration products and support you need to improve and streamline production

Consultation

Discuss your requirements with our experienced sales engineers to find the perfect custom-made solution.

Peace of mind

Trial our equipment at your plant or we can test your application at one of our onsite test facilities.

Ongoing support

We pride ourselves on excellent after sales support. For remeshing, servicing or technical support, our dedicated team are on hand.

The latest at Russell Finex

Keep up to date with the latest news and events.